Last November, I fried my 'lab power supply' that I made from a computer PSU. I was testing my solenoids and the stress was just too much for the PSU. The mistake I made was rapidly turning on and off my solenoid which likely resulted in voltage transients (spikes). Since the PSU does have a current limiter, it was likely the constant voltage spikes that caused the damage. There are various methods to suppress voltage transients such as by-pass capacitors and zener diodes. In particular solenoids and other inductive loads experience these voltage spikes, hence my no longer functioning bench power supply.

I could have just rebuilt the same power supply by adding binding posts etc to the PSU housing but after searching the internet an ATX power supply breakout board seemed a popular option. The main advantage compared to my old power supply was the addition of fuses on the outputs. The extra safety this provides is perfect for bench top testing of circuits.

|

| ATX Breakout Board |

Since I have not touched electronics for a long time, I though that this was a good opportunity to relearn how to design a PCB with EagleCAD. I essentially copied the ATX breakout boards from Dangerous Prototypes (via Seeedstudio) and Sparkfun.

The circuit is very simple. You have to short PS_ON pin to ground in order to turn on the power supply. The +5VSB (Standby) and PWR_OK pins can be used to add indicator LEDs. There is a place for a load resistor which is sometimes needed on the 5V in order to turn on the PSU. However, this was not required for my PSU. I also added in a 6-pin header for a ribbon cable with selectors for the voltage to make an easy plugin for a breadboard.

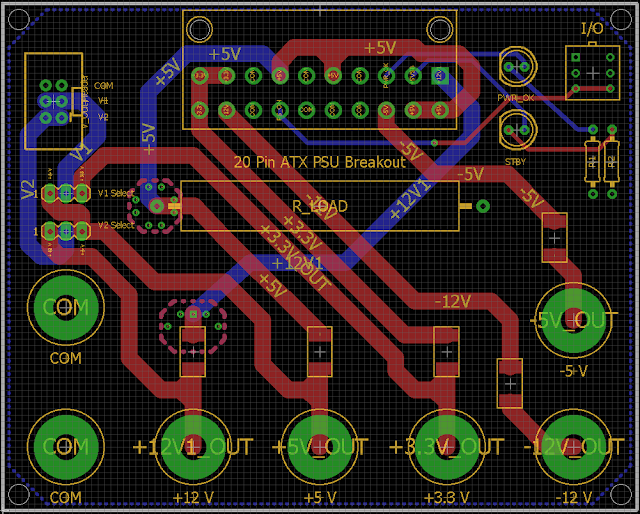

Despite the simplicity, I made a pretty bad error. In the photo above, you can see that the ATX header is solder in on the bottom of the board. I set the pinout for the header per the pinout below which is the pinout as viewed from the male connector. It should actually be the mirror image because the header is the female connector. Luckily I was able to rectify the issue by soldering the header to the bottom of the board. A corrected schematic and PCB layout can be seen below.

|

| ATX 20-Pin Pinout from Male-Connector via Wikipedia |

|

| ATX Breakout Schematic |

|

| ATX Breakout PCB Layout |

Note the additional vias where the +12V and +5V traces change layers. These are to ensure better connectivity and current capacity between the layers. I learned this layout technique from examining the Dangerous Prototypes ATX breakout board.

This was a fun simple project that helped me get back into electronics and relearn how to use EagleCAD. My advice though would be to just purchase the Dangerous Prototypes version as it has the same surface mount resettable PTC fuses. If you need the rails limited to a higher amperage, go for the Sparkfun setup as it is difficult to find cheap PTC fuses greater than 1.25A. Worse case, you can just jumper the fuses.

Comments

Post a Comment